The sight of the first snow on the horizon of Bill Wiley’s 500-acre farm in Shelby County, Ohio, is a welcome relief. The 2024 growing season has been incredibly dry.

“We are about eight inches behind regular precipitation for the year,” he said.

But Wiley, who farms corn, soybeans, wheat, pumpkins and gords, has installed two inline water control structures that control the flow of drainage water from two of his fields.

He hopes these devices can keep thousands of gallons of precious water — and expensive fertilizer — back in his fields, helping him achieve better yields while protecting the environment.

“Whatever you can keep in the soil, nutrient-wise, is better for you, and the environment,” he said.

Much of North America’s food is produced on land in the Midwest and within the Great Lakes basin that, without drainage, would be too wet to be productive.

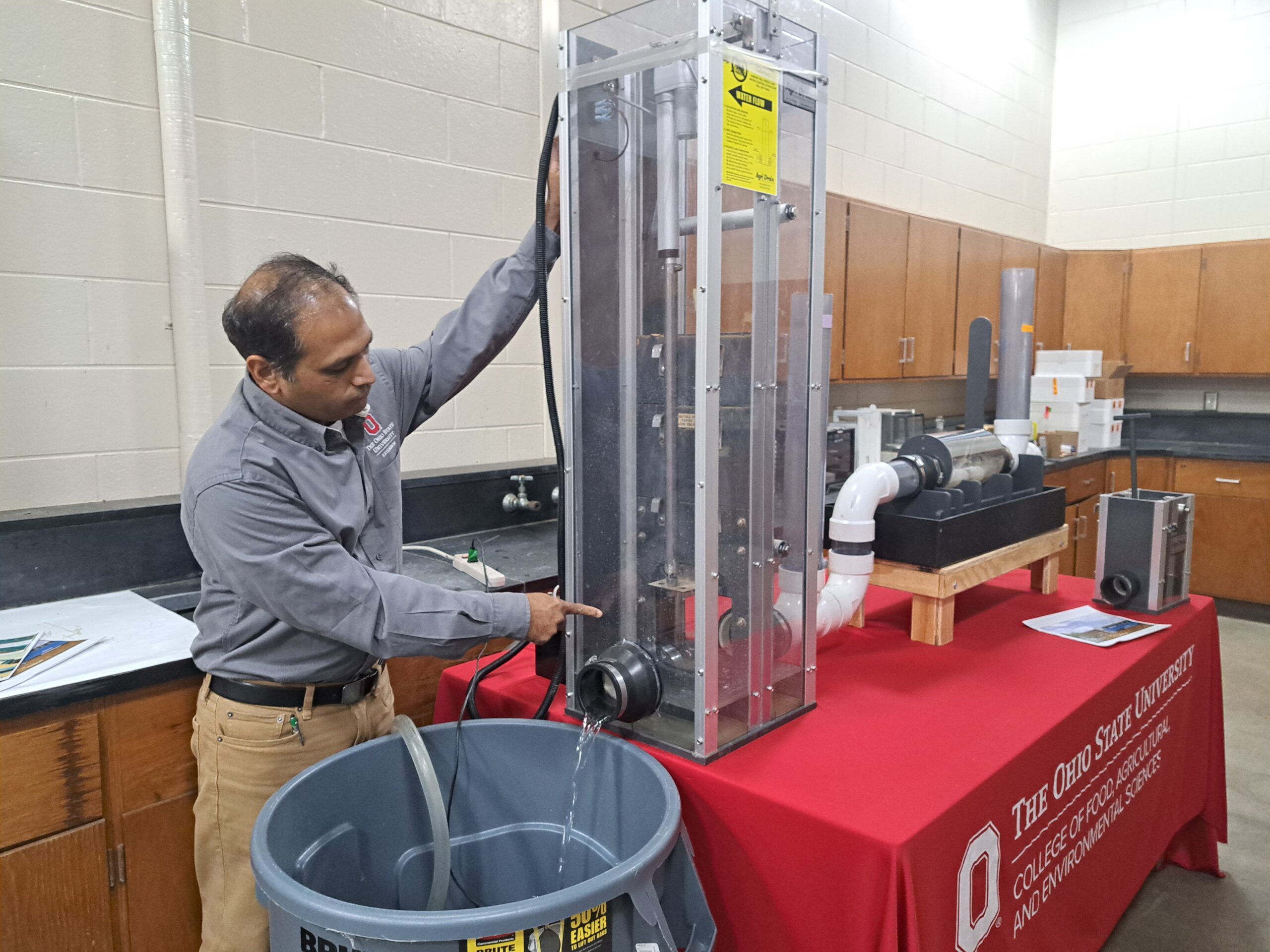

“Without drainage, agriculture cannot happen in the majority of the Midwest,” said Vinayak Shedekar, an assistant professor of agricultural water management at the Ohio State University.

As a result, around one-quarter of arable land in the U.S. and Canada is artificially drained.

But these drainage systems have a major shortcoming: in addition to carrying away excess water during and after flooding, they take nitrate and other fertilizer chemicals that can fuel conditions favorable for neurotoxin growth into public waterways, killing wildlife and threatening water supplies hundreds of miles downstream.

To counter this, researchers, companies and farmers such as Wiley are developing and deploying systems that can control that flow, benefiting landowners, water consumers and the environment alike.

Dr Shedekar said that 25 years of studies suggest these controlled drainage structures, manufactured by companies in Iowa, Indiana and beyond, have resulted in a 20 to 50% reduction in nitrate loads coming out of drainage outlets.

“What we’re doing is turning on and off drainage for whenever you need or don’t need it.”

Water, water everywhere

“What we’re doing is turning on and off drainage for whenever you need or don’t need it,” says Dr. Vinayak Shedekar of the Ohio State University. (Photo Credit: Stephen Starr)

Around 40 million people in cities and towns such as Toronto, Buffalo, Toledo and Chicago rely on the Great Lakes for their drinking water. Thousands of people in the recreation and tourism industries need clean Great Lakes water for their economic survival.

Yet agriculture runoff is a major environmental problem for the wider Great Lakes region.

Nitrates and phosphorus act as a fuel for the dangerous algae bloom growth that’s increasingly common in the western Lake Erie basin during the summer months.

Roundly seen as the most polluted Great Lake, Lake Erie has been hit particularly badly by agricultural runoff, in large part from the heavily-polluted Maumee River that flows into the lake at Toledo in northwest Ohio.

The western basin of the lake, just 120 miles from Bill Wiley’s farm, has struggled especially badly with elevated toxins from algae blooms, forcing the city of Toledo to spend a half billion dollars on a water purifying system following a 2014 contamination event that shut down water access for 400,000 people for days.

All the while, experts say that it’s here in the Great Lakes region, with its tens of millions of acres of flat and poorly drained soil, where controlling drainage water on farms can work best.

“We are working with hundreds of farmers, landowners, agencies and organizations annually,” said Ben Reinhart, a conservation planner at Ecosystem Services Exchange, a technical service provider that oversees the design and installation of a host of controlled drainage structures and devices.

“In northwest Ohio alone, hundreds of structures have been installed with help from Ohio’s department of agriculture and county-level soil and water districts.”

The company operates in the Corn Belt states, the Chesapeake Bay region, Arkansas and Mississippi.

According to Reinhart, if farmers can reduce drainage outflows by 40-50% then they can in turn reduce nutrient outflows by that same amount. This means farmers have the opportunity to improve their yields by 5-15%.

Manual inline water control structures — those that are raised and lowered by hand — cost between $1,000 and $2,000 each, with installation costing about the same, depending on pipe size and the height of the device, said Reinhart.

But to incentivize farmers, the US Department of Agriculture’s environmental quality incentives program typically pays for all design and engineering costs, and 75% of the cost to buy and install the structures. Many states and counties also have their own funding efforts to support farmers interested in deploying the systems.

Reinhart said that in recent years, innovations around automating the systems and newer conservation program delivery models have increased the level of interest from farmers and landowners.

“That’s really starting to provide some spark around interest and adoption from the engineering side of things,” he said.

“It definitely is a change of mindset for some folks. But I think there’s a growing awareness around the role of water in agriculture, not just from having too much water (but) a lot of years there are periods when we don’t have enough.”

Life in the field

Farmer Bill Wiley stands behind one of his inline water control structures in Shelby County, Ohio. (Photo Credit: Stephen Starr)

For the most part, crop farmers such as Wiley only typically need to get into their fields with heavy machinery three to four times a year, for planting, fertilizing, spraying and harvesting — in the case of soybeans and corn, the two most popular crops grown in the Great Lakes region.

Wiley opens his drainage control devices in late March so that his fields are as dry as possible in time for planting and spraying.

“My thinking is if you had an overabundance of moisture during the season, to the point that it could cause damage to certain low areas, you can open them right up,” he said.

In late May, he closes them until the end of August or September, when harvest of his soybean crop begins, and machinery needs to get into his fields again.

With many experiencing warmer and drier growing seasons across the Great Lakes in recent years, these systems can also be helpful to farmers suffering from the fallout of drought, an issue that’s likely to be exacerbated as the effects of climate change take hold in the years and decades ahead.

With storms and flash flooding also expected to become a more prominent climate pattern, farmers, who rely heavily on regular and light precipitation for optimal growth conditions, risk losing residual moisture in their soil to these high-volume, short-lived weather events.

“After harvest and cover crop planting is done, I close the system for about four months,” said Wiley. “In theory it makes sense — that if you’re stopping the flow and you have the inline water control device high enough it should hold more water in the water table.”

Challenges

One of the challenges Bill Wiley faces is physically lifting and dropping the slides that prevent or allow drainage water from leaving the soil under his fields. (Photo Credit: Stephen Starr)

But the devices, which only work on land with existing drainage infrastructure in place, are not without their challenges.

“It involves effort by the farmer to move the slides at certain times of the year (and) we don’t know the extent to which it is being used by everyone,” said Jane Frankenberger, a professor at Purdue University and project director of the Transforming Drainage project.

She said it’s also important to point out that just because nitrogen fertilizer is kept back in the fields and out of waterways by the control structures, it doesn’t mean it always remains available to the crop.

“The question for [farmers] is whether it will have yield benefits,” said Frankenberger. “They don’t need to spend a lot of money (on the devices), but they do need to spend some time.”

For Wiley, who has around one hundred acres of his cropland drained through the water control structures, the time and effort involved in raising and dropping the slides that control the water flow can be an issue.

“The main limitation on this is that the slides slide up and down and it’s getting progressively more strenuous for me to move them,” said Wiley. “You are supposed to take them all out and grease them.”

Wiley continued: “If you’ve got 3,000 acres and you need to go around to each device, you’re talking about 80 visits to open each one up. There’s no way farmers can keep up with that in a timely manner.”

What’s more, the extent to which these devices can keep phosphorus and phosphates out of waterways is in the early stages of scientific research.

“Phosphorus is a more complex constituent to study — it has its own behavior within the soil profile,” said Dr Shedekar of the chemical element that’s essential for growing productive, healthy crops but which can increase aquatic plant growth and reduce water oxygen levels, killing plants and fish. “But my program is confident that you can use these (drainage control) practices for effectively reducing the phosphorus loss at the edge of a field.”

Solutions

The drainage water control devices block water from leaving a field by a series of slides that can be moved up and down. (Photo Credit: Stephen Starr)

Recent years, however, have seen fixes to the challenges being experienced by farmers such as Wiley emerge.

Automated water control structures that can operate from a phone or computer, are programmable for months at a time and cost around $7,000 to $10,000 each, are growing in popularity. As with the manual systems, the majority of the cost of these devices and their installation is covered by federal or state grant programs.

“More and more people want to be able to manage these things remotely and automatically,” said Charlie Schafer, the co-founder and owner of Iowa-based Agri Drain, the sister company of Ecosystem Services Exchange and which manufactures and sells the drainage water control systems used by Wiley in the field and Dr. Shedekar in the university lab.

The company has sold “thousands” of drainage control structures, Schafer said, and are used for controlling water on golf courses, on fish farms, agricultural land and for wetland management.

A newer challenge Agri Drain and researchers are meeting, and one which Wiley highlighted, is figuring out how to keep water stored underneath fields that have greater elevation change.

Dr Shedekar has had success with ‘water gates’ placed inside the drainage pipe that use small flotation devices to block water from flowing through the underground drainage system. Just one or two additional feet of subsurface water storage can amount to thousands more gallons of water stored in a field.

Right now, in the heart of winter, Wiley is content knowing that much of the water that falls between now and planting time next spring will stay on or underneath his fields, where it needs to be.

“Because it’s been so dry, I want them closed now. This (drought) is the worst it’s been in Ohio for decades,” he said.

But he’s also cognizant that with more extreme weather patterns expected in the years to come, he will likely become ever more dependent on his water control devices.

“We’re going to have heavier rain, we’re going to have longer, more intense droughts,” he said.

“So it’s logical to me that this system should help bridge some of those extremes in trying to keep water in the soil.”

Catch more news at Great Lakes Now:

U.S. Movement to Limit CAFO Pollution Emboldened by Michigan Court Ruling

Oberlin Food Hub brings fresh produce to Ohio’s food banks while supporting local farmers

Featured image: “The main limitation on this is that the slides slide up and down and its getting progressively more strenuous for me to move them,” says Ohio farmer Bill Wiley. (Photo Credit: Stephen Starr)